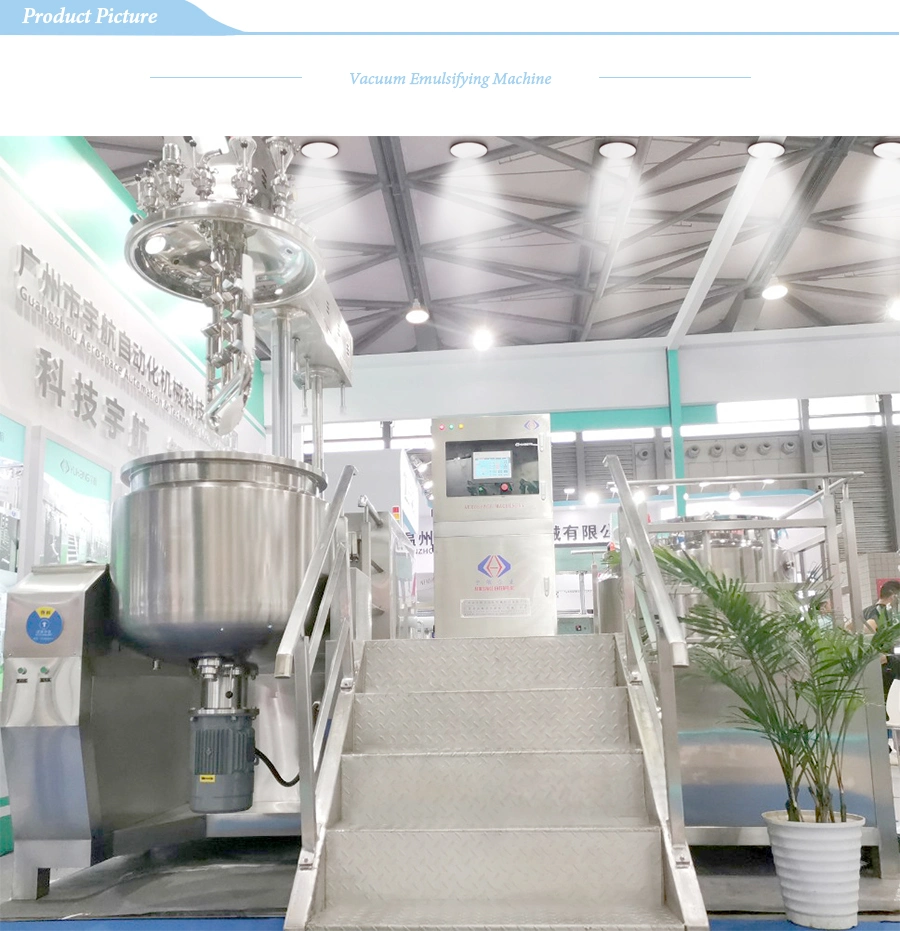

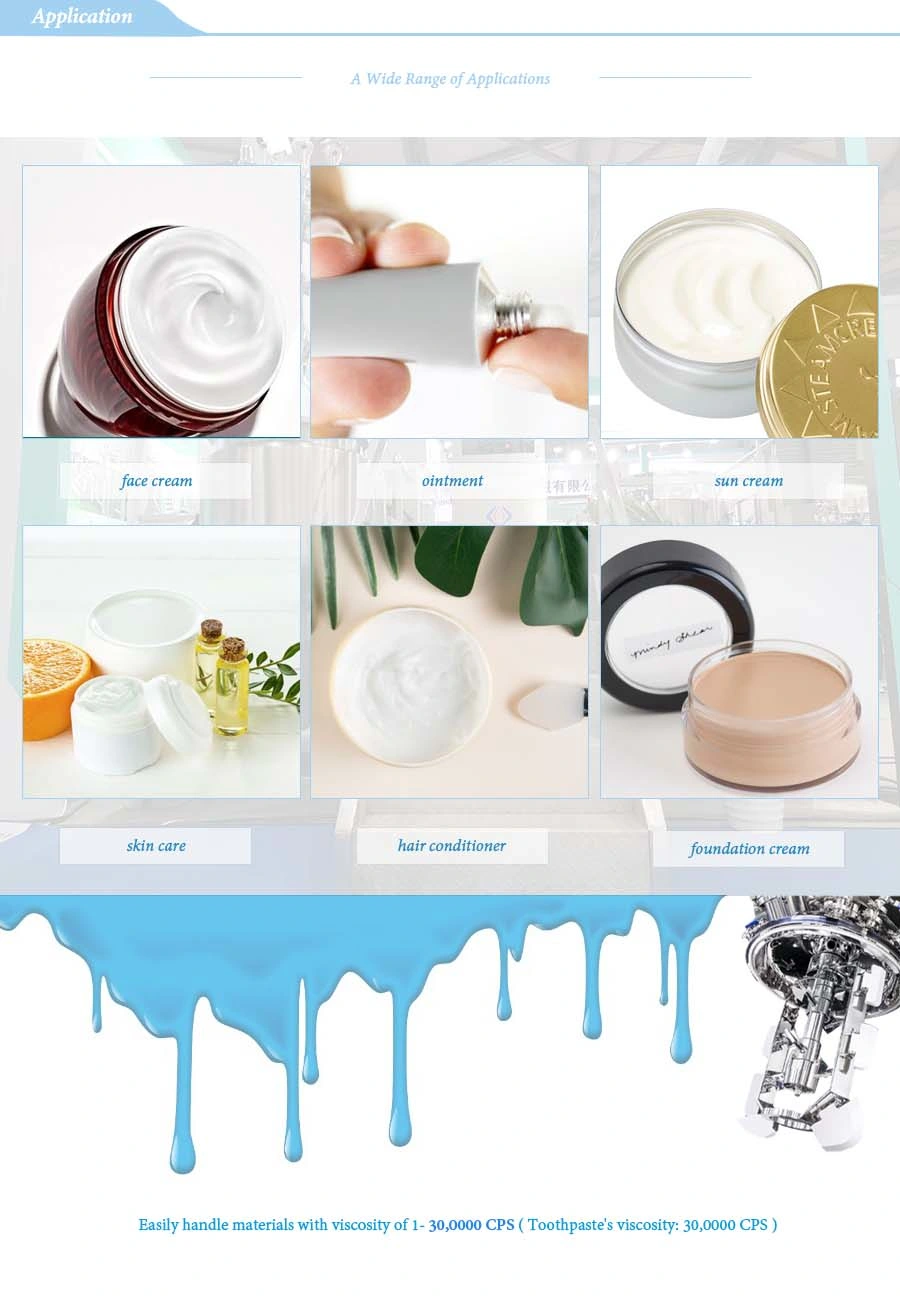

Vacuum Emulsifying Machine is suitable for the production of cosmetic cream, skin cream, eye cream, hair conditioner, hair dye cream, ointment, emulsification and ointment, which need to be emulsified and stirred under the vacuum condition. Our vacuum emulsifying Machine is a customizable equipment, which can be reasonably configured according to the customer's specific requirements.

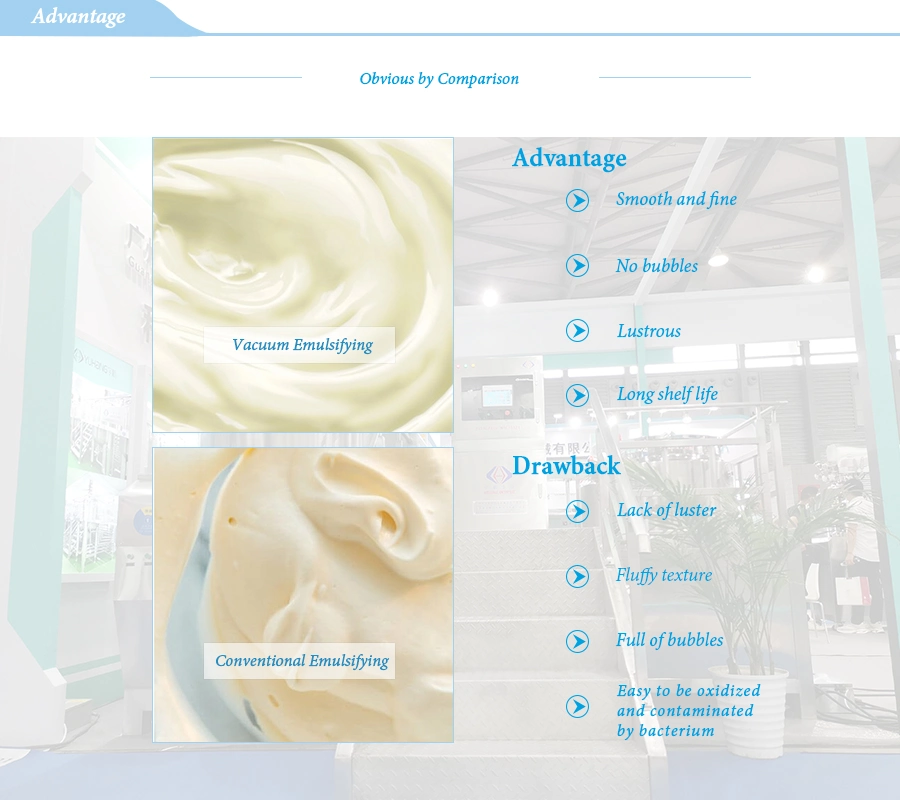

With the help of precise processing technology, and high cooperation between rotor and stator, high-speed rotation of powerful motor causes vacuum between rotor and stator, and materials are inhaled from the top of rotor and stator to the gap in between. The strong kinetic energy makes the rotor produce extremely high linear velocity, which makes the material fly out after strong impact, crushing, centrifugal extrusion, liquid layer friction and strong shearing between the gap of rotor and stator, and generate strong turbulence under the action of various forces in different directions. The stable emulsion was produced by depolymerization, dispersion, homogenization, refinement and shearing of the material with a certain amount of emulsifier.

Other Features:

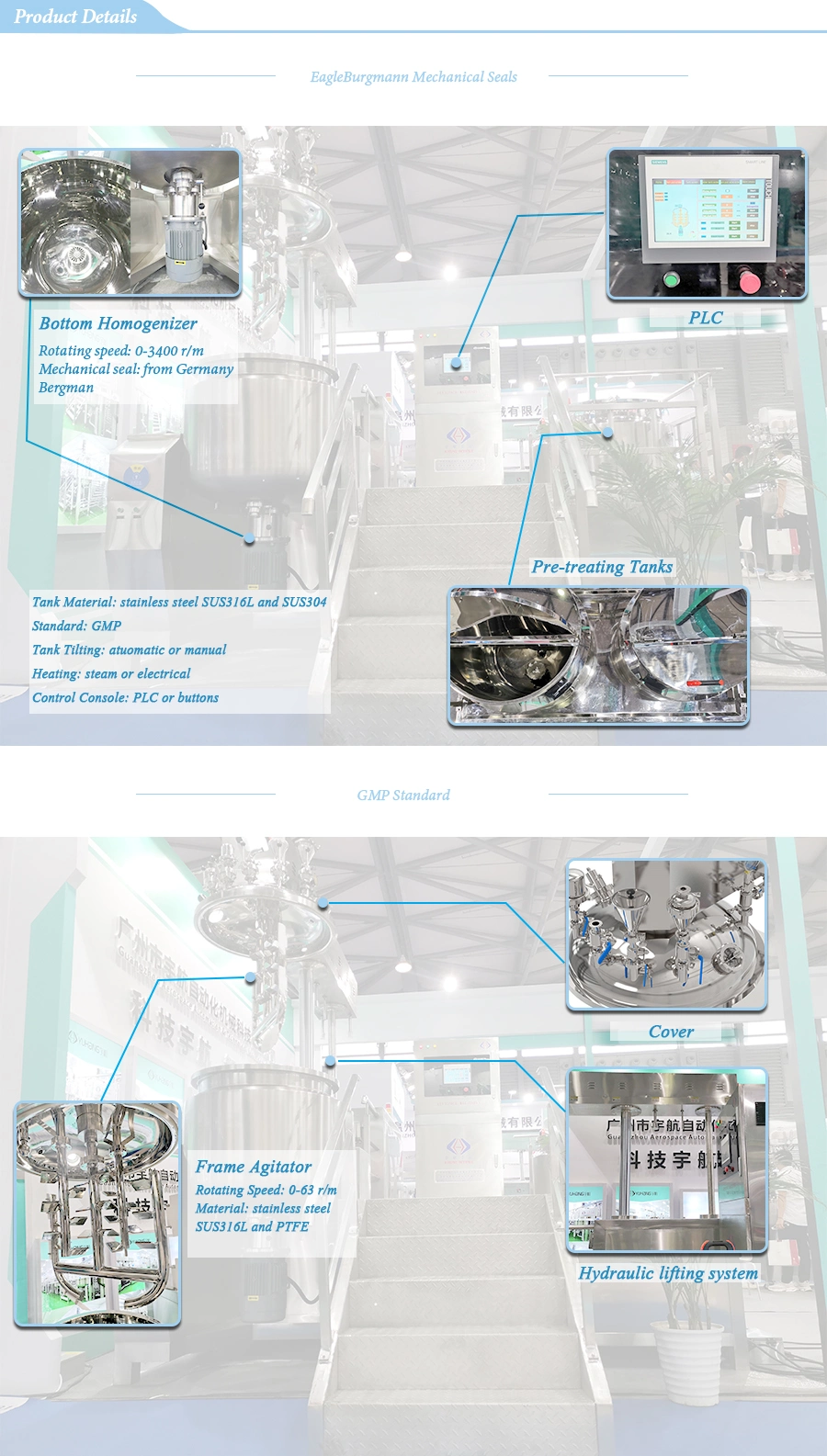

- The emulsification process of the main pot is carried out under the condition of full sealing, which prevents the pollution of dust and microorganism.

- The material in the water pot and oil pot are added to the main pot by means of vacuum feeding. The main pot can be heated or cooled.

- The material in the pot can be emulsified by high-speed internal circulation shear of homogenizer and can be mixed clockwise or counterclockwise. Clockwise mixing is frame scraping wall mixing and counterclockwise mixing is slurry mixing.

- The scraper agitator has centrifugal effect during operation, making the PTFE scraper cling to the wall of the pot, which can effectively solve the problem of material staining on the wall of the pot and no dead angle.

- The frequency conversion speed regulating device can adjust the speed steplessly.

- Homogeneous mixing and paddle mixing can be used separately or at the same time.

- Material dispersion, homogenization, emulsification and mixing can be completed in a short time.

- Homogeneous emulsification technology originally from Germany is specially designed for refined and homogeneous products. The vacuum emulsifying mixer can be equipped with wall scraping type or ribbon type and other types of agitation, so as to easily handle materials with viscosity of 1-300000 CPS.

- Real time measurement and control parts can easily control the temperature, pressure, pH value and other parameters.

- The main parts are made of international famous brands which are fine materials.

- The structure of Vacuum Emulsifying Mixer is brief and reasonable with simple operation.

- The design and technology of vacuum emulsifier are strictly met with GMP standards.

- Vacuum emulsifying mixers are the ideal machines for making cream, lotion, ointment and suppository.

The examples above only concerns daily necessicities and cosmetics. In fact, the applications of this machine is wide enough to shock you.

The chart below is for your reference.

| Fine chemicals | plastics, fillers, adhesives, resins, silicone oils, sealants, pastes, surface active agents, carbon black, defoamers, brighteners, leather additives, coagulants, etc. |

| Petrochemical industry | heavy oil emulsification, diesel emulsification, lubricants, etc. |

| Daily chemicals | washing powder, concentrated washing powder, liquid detergent, various cosmetics, skin care products, etc. |

| Paint and ink | latex paint, interior and exterior wall paint, water-based oily paint, nano paint, paint additives, printing ink, printing ink, textile dyes, pigments, etc. |

| Biomedicine | sugar coating, injections, antibiotics, protein dispersions, medicated creams, health products, etc. |

| Pesticides and fertilizers | pesticides, herbicides, medicated emulsifiable concentrates, pesticide additives, fertilizers, etc. |

| Food industry | chocolate shell, fruit pulp, mustard, slag cake, salad dressing, soft drinks, mango juice, tomato pulp, sugar solution, food flavor, additives, etc. |

| Nano materials | nano calcium carbonate, nano coatings, various nano material additives, etc. |

| Road asphalt | ordinary asphalt, modified asphalt, emulsified asphalt, modified emulsified asphalt, etc. |

The data sheet below is for 500L type. If you need the specific data of other volume choices, please send us an inquiry, we will include a more comprehensive and specific data sheet inside the quotation for your reference. Delivery date and payment terms will also be inside.

| Manufacturer | Yuhang Machinery Factory | ||

| PN | 500L vacuum emulsifying machine | ||

| Capacity | Design volume: 600L, working capacity:500L | ||

| Tank Cover | Liquid(particle)inlet, sunk material inlet, air inlet with filter, inspect light and sight glass, vacuum port, pressure meter(1 to -0.1 bar), pressure clamp | ||

| Blending tank | Material | Inner layer: SUS316L thickness: 6mm | |

| Middle layer: SUS304 thickness: 6mm | |||

| Outside layer: SUS304 thickness:5mm | |||

| configuration | Bottom material outlet, size: 1.5" | ||

| Temperature sensor (0-199ºC) | |||

| Electrical heating: 8kw or Steam heating( requires steam generator) | |||

| Blending system | Homogenizer | 1. Mechanical seal: German Burgmann Technique 2. Power: 7.5kw/380/50Hz; RPM: 0--3400R/Min | |

| Wall scraper and Frame Agitator | Frame Agitator Material: SUS316L, Wall Scrapper material: PTFE | ||

| 1. Power: 1.5 kw/380V/50Hz; RPM:0~63r/min (Frequency convertor control) | |||

| Safety: 1. During the the blending process, the cover can not be opened. 2. When the cover being lifted, the blender can not rotate. | |||

| Vacuum system | 1. Vacuum pump: water recycle, power 1.5kw/380V/50Hz 2. Pressure sensor (Under vacuum condition, the hydraulic cover can not be opened) | ||

| Heating method | Electrical heating or Steam heating( depends on your productivity and manufacturing technique, we will offer suggestion) | ||

| Pressure | Pressure in the blending tank when working: -0.090 Mpa; Jacket working pressure:0.2 Mpa | ||

| Control box | SUS304 , 2mm thickness | ||

| Dimension | 382* 285* 255 mm | ||

| Stainless steel shelf, platform and guardrail | |||

| Spare parts | One year spare parts and tools | ||

| Guarantee | One year | ||

| Using life | More than 15 years | ||

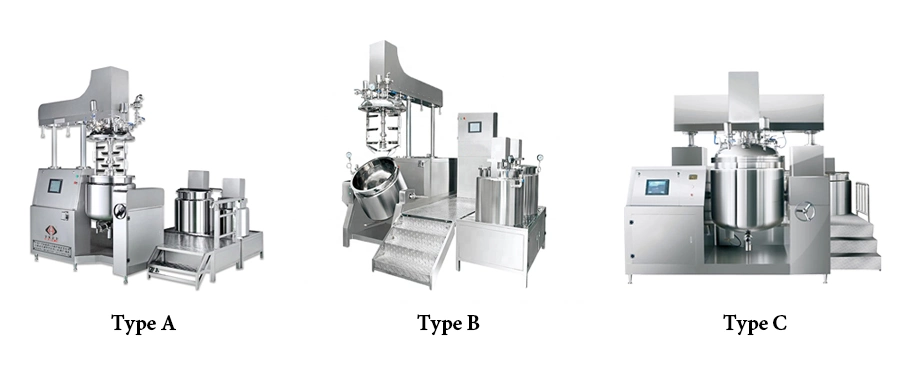

Currently we have three kinds of design as your choices:

You can tell us the type you prefer when sending the quotation.

1. Can this machine be customized?

Yes, this machine can be customized.

2. I am planning to set up a new factory but I don't have any relavant exprience, how can you help me?

Based on the information you provide and your specific requirements, our salesmen will recommend the most suitable machine or the whole production line to you.

3. I don't know how to install and operate the machine, how can you help me?

We would offer instructions of the machine. The water treatment machine is fully installed when being sent, so you don't need to worry the installation and our engineers will instruct you in operating the machine through video call or field training.

4. How long is the production period of a machine?

Normally it takes 10-14 days to produce a vacuum mixing machine. Sometimes we have machines in stock.

5. If I want to check the machine production progress, can you offer such service?

Yes, we can. We will use whatsapp or wechat to video call to you and show you the production progress. If you are not convinient for any video call, we can shoot some videos or take some pictures for you. If you can be here to check it yourself, it will definitely be the best way.

6. I don't have any import experience, can you help me with the customs and transportation?

Yes, we can. Having been producing and exporting machines for 20 years, we cooperate with lots of forwarders and shipping companys. We can offer the best sulotion to you.