Product Introduction

Belt filter press The belt filter press dehydration process can be divided into four important stages: pretreatment, gravity dehydration, wedge zone pre-pressing dehydration and squeezing dehydration.

Sludge fully reacts with coagulant will flow into material distributor in concentration part then dewatered along the movement of filter cloth under two-way guidance of mud rake and gravity. Reverse mechanism will transfer sludge to gravity dewatering area for further dehydration and in S-shape area pressed by roller with different diameters, sludge is again dehydrated between upper-lower filter cloth. Finally it will be scraped and cloth be cleaned during operation automatically. It features large productivity and high dewatering capacity and is applicable for treating sludge produced from tailings, ethanol residue, coal mud, paper mill , slaughter industry and car wash factories etc.

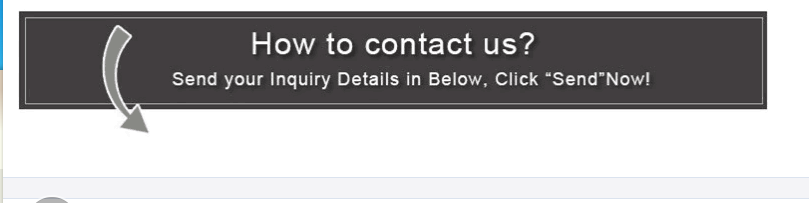

Application Range

Belt filter press are mainly used in sand washing mud treatment, construction pilling mud treatment, coal washing mud treatment, mineral mud treatment, and can also be used in papermaking sludge, textile printing and dyeing sludge, leather sludge, food factory activated sludge, ceramics marble polishing sludge, electroplating sludge, clean coal dewatering in coal washing plants, sedimentation sludge in river ponds, organic sludge in chemical plants, etc. The mud cake and clean water produced after treatment can be directly discharged or recycled to achieve zero discharge of sewage.

Advantage

1,Can keep working constinuously for long time.

2,Simple operation, convenient management and easy maintenance.

3,Large processing capacity, high dehydration efficiency.The moisture content of the filter cake is lower than other company equipment.

4,Adopt advanced frequency conversion speed relugation, which can effectively control the processing speed.

5,Equipped with fully automatic dosing device, effectively save personnel management time.

6,Both sides have cylinder deviation adjustment devices, which can effectively prevent the deviation of filter cloth. Technical data

Technical data

There are several models you can choose.

Model | Capacity (m3/h) | Power (kw) | Air compressor power(kw) | Bandwidth (mm) | Feeding concentration (%) | Pulping concentration(%) |

TLYL500 | 0.5-4 | 0.75 | 1.1 | 500 | 3-8 | 25-40 |

TLYL1000 | 3-6.5 | 1.5 | 2.2 | 1000 | 3-8 | 25-40 |

TLYL1500 | 4-9.5 | 1.5 | 3 | 1500 | 3-8 | 25-40 |

TLYL2000 | 5-13 | 2.2 | 4 | 2000 | 3-8 | 25-40 |

TLYL2500 | 7-15 | 4 | 5.5 | 2500 | 3-8 | 25-40 |

TLYL3000 | 8-20 | 5.5 | 5.5 | 3000 | 3-8 | 25-40 |

Our Services

Our Services

Shandong Tianlang Environmental Protection Technology Co., Ltd. is a high-tech enterprise integrating environmental equipment production and R&D. The company is located in Zhucheng City, Shandong Province, with beautiful scenery. It has convenient transportation because it nears Qingdao and Rizhao seaport.

Covering an area of 80,000 m2, the company has advanced production line and production technology. By absorbing the advanced manufacturing concepts and sewage treatment experience of the same industry at home and abroad, it has cooperated with many well-known sewage treatment experts and universities. It has Strong non-standard design and manufacturing capabilities, perfect production testing equipment, complete manufacturing specifications, stable and reliable product quality.

As a production and research enterprise for environmental protection equipment, the company mainly develops and produces sewage treatment equipment, sludge dewatering equipment, waste gas treatment equipment, manure fermentation equipment and waste incinerator. Products are widely used in agriculture, aquaculture, petroleum, chemical, paper, pharmaceutical, food, starch, metallurgy, slaughter, printing and dyeing and other fields. There are dissolved air flotation machine, integrated sewage treatment equipment, MBR bioreactor, mechanical filter, disinfection equipment; belt filter press, plate and frame filter press, screw dewatering machine and waste incinerator nearly 100 kinds of products and accessories. trusted by the majority of users, it become the backbone of China's environmental protection industry.

In the face of fierce competition in the market, our company adheres to the business philosophy of ""Focus on quality, keen on innovation", continuously strengthens the product research and development, so that the product has a broader market.

Looking forward to the future, we will continue to provide more high-quality products and prompt and sincere service to customers, and supply environmental protection solutions to you.

Q:How to buy your idea products?

A:What's the material you are going to deal with? What's the size of solid ? What's the solid percentage (%) ?

Q:How to pay?

A:TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

Q:What is the delivery time?

A:It depends on order quantities. Generally speaking, the delivery time will be within 3 to 4 weeks.

Q:How to keep your equipments from corrosion?

A:We use the world-famous paint, like SigmaCoatings,PainBow,etc. What's more, we paint strictly according to the standard process.