Introduction of Integrated Automatic Filter Press

This model is an integrated automatic filtration equipment,with characteristiccs of high degree of automation, stable performance,safe and reliable,etc. It is the first choice for customers in such industries as metallurgy, gas, paper making, coking, pharmacy, foodstuff, brewing, fine chemical industry and sewage treatment. It has been widely used in the fields of solid-liquid separation. Compared with the traditional filter press, it has added the filter cloth cleaning system, automatic drip tray system,vibrating device, etc.The intelligent control system to make the equipment operation safe and reliable.

Advantages of Our Produced Filter Press

1.Structure is made of Q235 high quality carbon steel. It adopts automatic welding, solder side is flat, weld-joint is solid and durable, it can perfectly avoid distortion. It has reached the advanced technology in Europe and the United States.

2.Main-beam is processed by high speed centrifugal sand blasting to remove rust and iron oxide scale, then painted by epoxy micaceous iron primer to get better rustproof and corrosion resistance effect.

3.Side bar is covered by stainless steel 304 shell to protect itself from wearing. The smooth surface of shell also make plate shifting more easily.

4.Plate is made from PP. It is tasteless and non-poisonous, safe with food and pharmacy industry. It is characterized by light weight, easy operation, acid and alkali resistance, high temperature and high pressure resistance.

5.Hydraulic system adopts ABB motor, it is steady in operation and easy in maintenance. Pistons are made of steel #45 after surface specially processed to get better anti-wearing and high hardness performance.

6.Electric control cabinet adopts renowned electrical components, it can realize auto closing, auto opening, auto pressure maintaining and trouble-free operation.

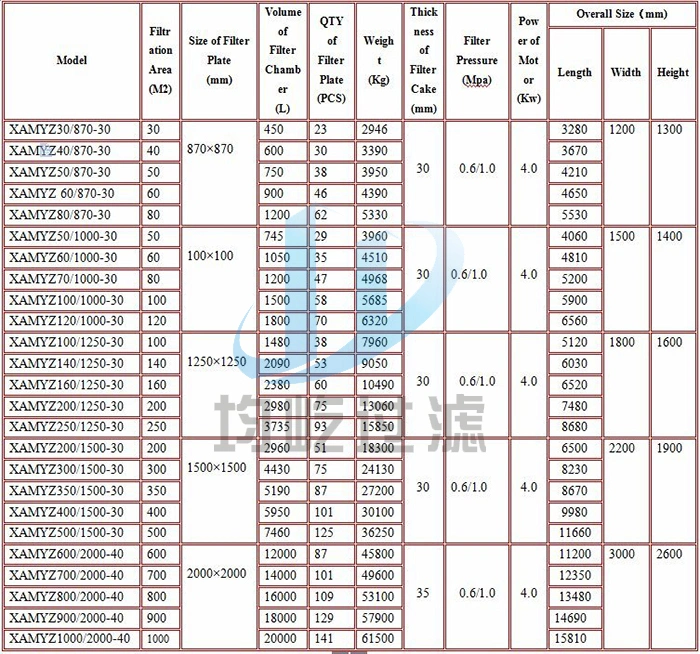

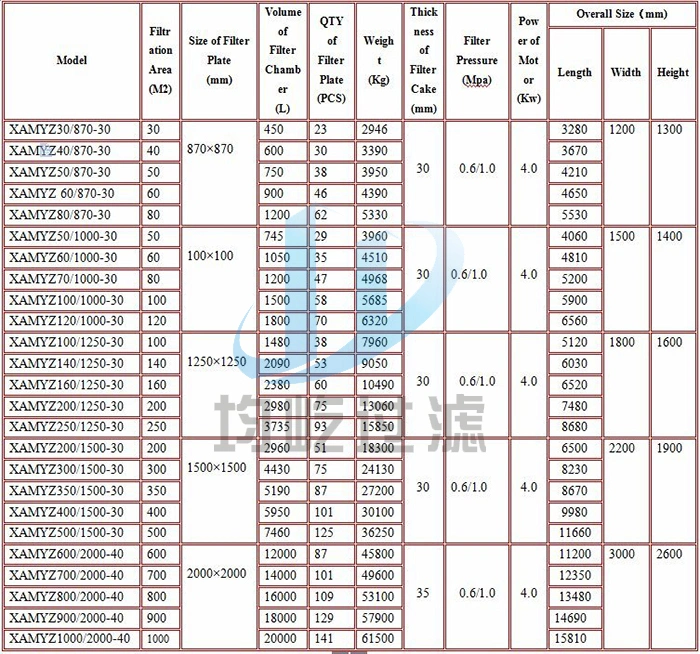

Some models of the filter press for your reference only

The optional systems for the automatic filter press

The quality depends on the fine processing

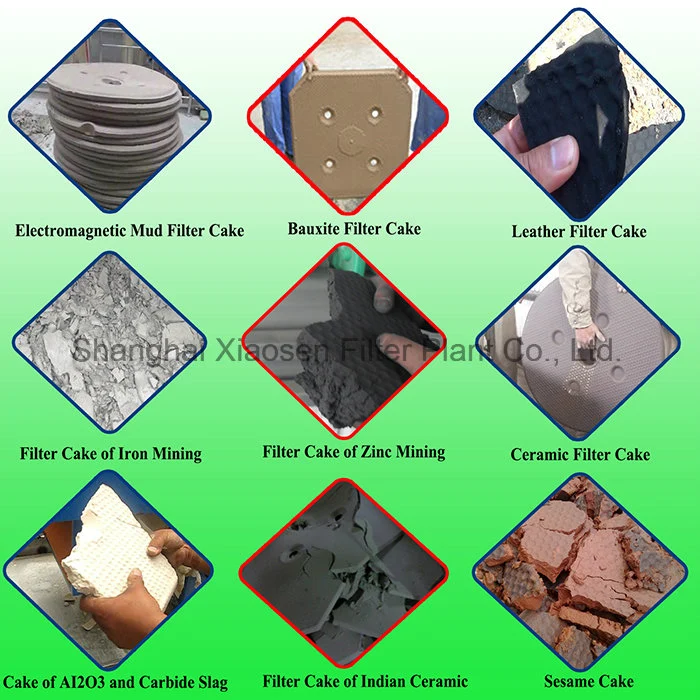

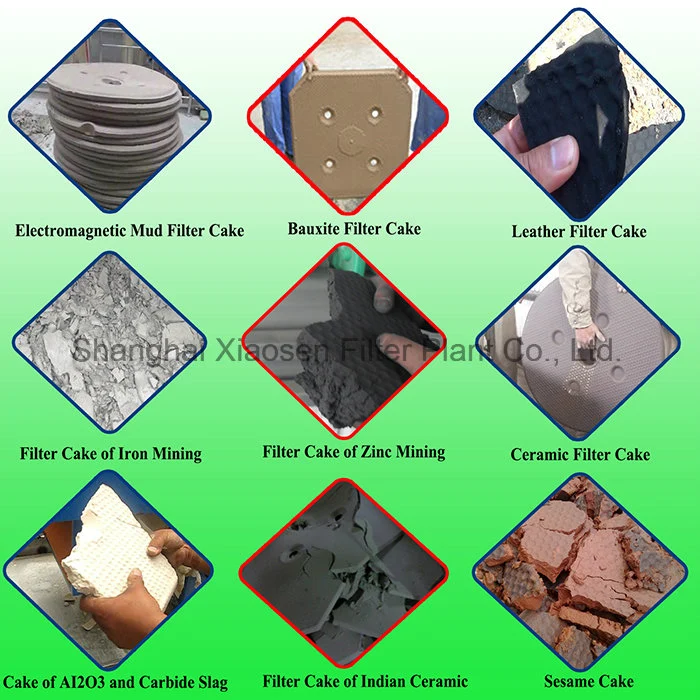

Different kinds of the cake after it is processed by the filter press

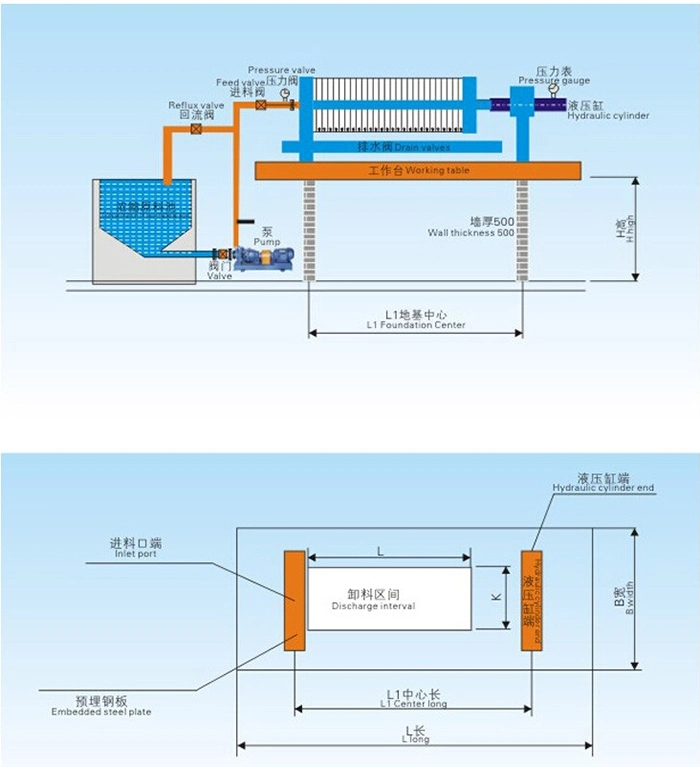

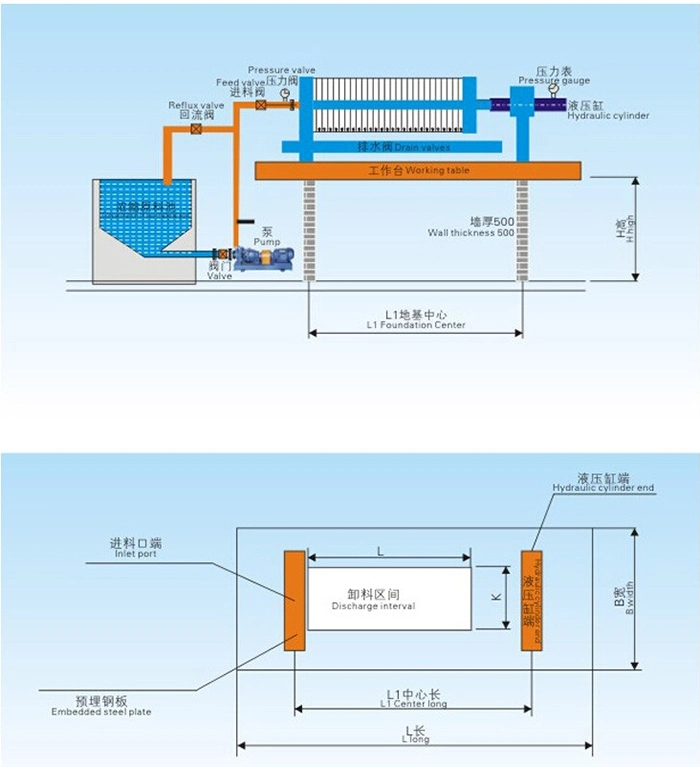

Pipe Connection and Feeding Process Diagram of Filter Press

Customer Visiting on Peru Expo Mina Fair

Pre-sale and after-sale service

Pre-sale service:

1.Your inquiry will be replied within 6 hours.

2.Help you to select suitable model

3.Design totally according to your requirements

After-sale service:

1.Provide 12 months warranty period and you will have our technology support forever

2.Engineering available to offer the service to your machinery overseas

Frequently asked questions

1.Q: Can you provide us the detailed drawing?

Yes, we can provide you the drawing after have made the prepayment.

2.Q: Are you a manufacturer or a trader?

We're a professional and experienced manufacturer located in Shanghai.

3.Q: Can you accept OEM?

Yes, we can produce the machinery totally according to your design standard.

4Q: How about the delivery time?

Normally 10-20 working days after prepayment, and we promise we will make the delivery as soon as we can.

Contact us

This model is an integrated automatic filtration equipment,with characteristiccs of high degree of automation, stable performance,safe and reliable,etc. It is the first choice for customers in such industries as metallurgy, gas, paper making, coking, pharmacy, foodstuff, brewing, fine chemical industry and sewage treatment. It has been widely used in the fields of solid-liquid separation. Compared with the traditional filter press, it has added the filter cloth cleaning system, automatic drip tray system,vibrating device, etc.The intelligent control system to make the equipment operation safe and reliable.

Advantages of Our Produced Filter Press

1.Structure is made of Q235 high quality carbon steel. It adopts automatic welding, solder side is flat, weld-joint is solid and durable, it can perfectly avoid distortion. It has reached the advanced technology in Europe and the United States.

2.Main-beam is processed by high speed centrifugal sand blasting to remove rust and iron oxide scale, then painted by epoxy micaceous iron primer to get better rustproof and corrosion resistance effect.

3.Side bar is covered by stainless steel 304 shell to protect itself from wearing. The smooth surface of shell also make plate shifting more easily.

4.Plate is made from PP. It is tasteless and non-poisonous, safe with food and pharmacy industry. It is characterized by light weight, easy operation, acid and alkali resistance, high temperature and high pressure resistance.

5.Hydraulic system adopts ABB motor, it is steady in operation and easy in maintenance. Pistons are made of steel #45 after surface specially processed to get better anti-wearing and high hardness performance.

6.Electric control cabinet adopts renowned electrical components, it can realize auto closing, auto opening, auto pressure maintaining and trouble-free operation.

Some models of the filter press for your reference only

The optional systems for the automatic filter press

The quality depends on the fine processing

Different kinds of the cake after it is processed by the filter press

Pipe Connection and Feeding Process Diagram of Filter Press

Customer Visiting on Peru Expo Mina Fair

Pre-sale and after-sale service

Pre-sale service:

1.Your inquiry will be replied within 6 hours.

2.Help you to select suitable model

3.Design totally according to your requirements

After-sale service:

1.Provide 12 months warranty period and you will have our technology support forever

2.Engineering available to offer the service to your machinery overseas

Frequently asked questions

1.Q: Can you provide us the detailed drawing?

Yes, we can provide you the drawing after have made the prepayment.

2.Q: Are you a manufacturer or a trader?

We're a professional and experienced manufacturer located in Shanghai.

3.Q: Can you accept OEM?

Yes, we can produce the machinery totally according to your design standard.

4Q: How about the delivery time?

Normally 10-20 working days after prepayment, and we promise we will make the delivery as soon as we can.

Contact us