| Configuration list of stacked screw sludge dehydrator | ||

| Sludge dewatering | KDDL301A | |

| processing capacity | 30~60kg-DS/h | |

| Total power | 0.75kw | |

| Overall dimensions | L3250×W950×H1750 [mm] | |

| Power supply mode | Power loop 3φ 380V/50Hz Control loop 1φ 220V/50Hz(110V/60Hz) | |

| Water supply pressure | 0.1~0.2Mpa | |

| work environment | temperature -10ºC~40ºC(Do not freeze) Maximum humidity90%RH (Do not condense) | |

| Main configuration | project | technical parameter |

| Spirochete body | Specification × length × quantity | Φ300×2273mm×1 |

| Material / specification | Dehydration Department:SUS304 Brand: Shanghai Baosteel | |

| Concentration section:SUS304 Brand: Shanghai Baosteel | ||

| Body support:SUS304 | ||

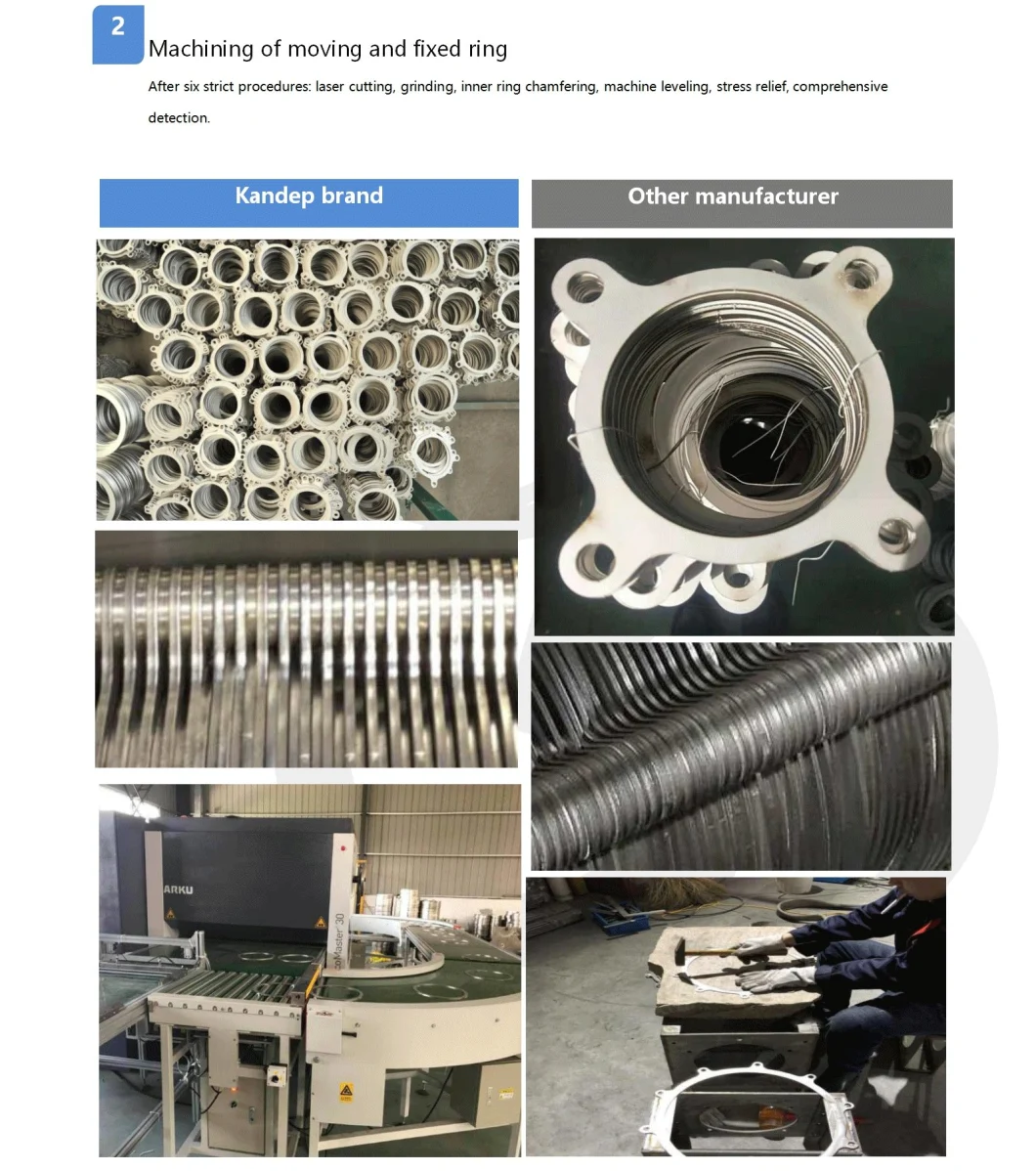

| Screw shaft processing | Hardness of SUS304 / super wear resistant cemented carbide coating 1300HV | |

| form | Modular design, sectional loading and unloading | |

| Double screw body stand | Specification × length × quantity | L2660×W720mm×1Set |

| texture of material | stainless steelSUS304 | |

| Filtrate outlet / specification | DN100×1 | |

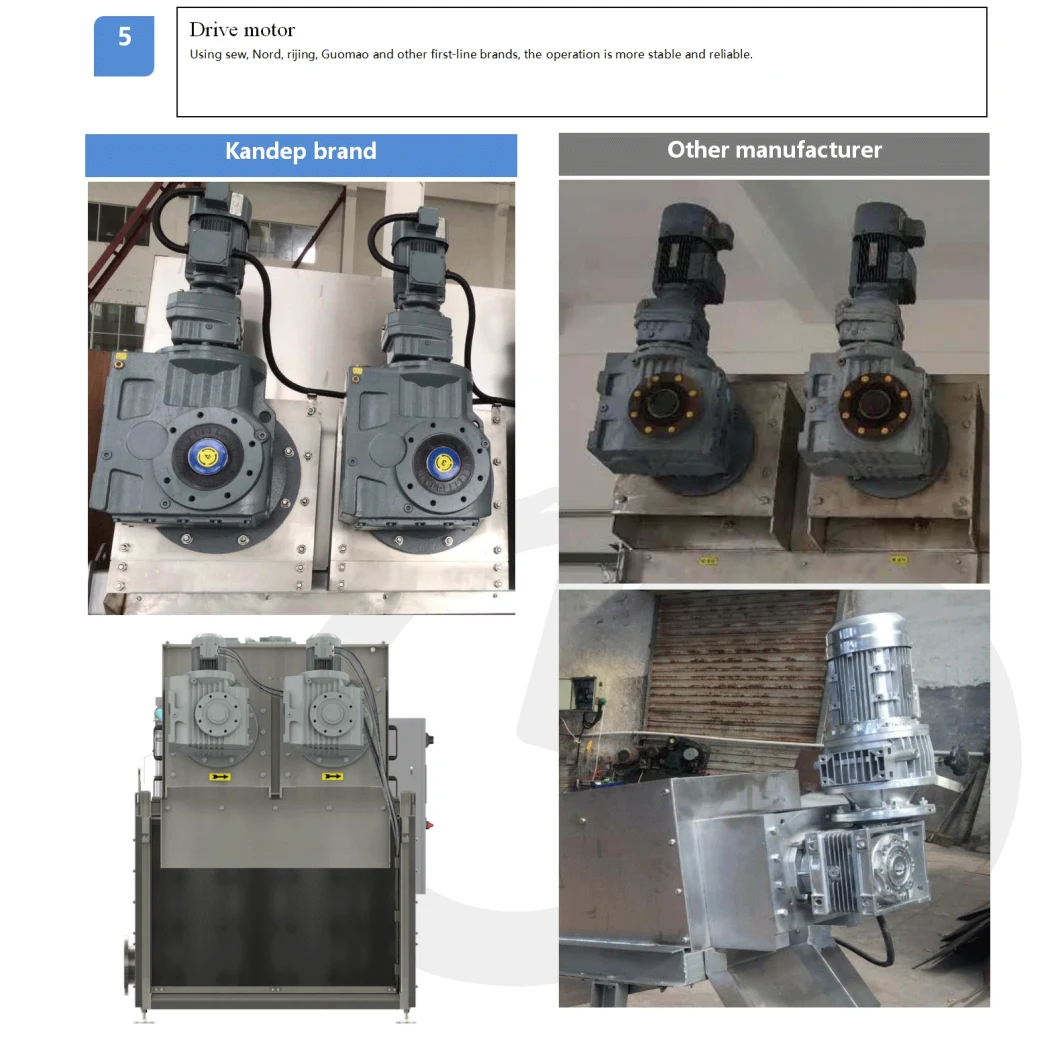

| Drive motor | power | 0.55[kw]×1(frequency conversion) |

| quantity | 1Set | |

| Protection level | IP55 | |

| Insulation class | F | |

| brand | SEW | |

| Flocculation mixing tank | Flocculation tank | : stainless steel SUS304 brand: Shanghai Baoste size:L1010×W600×H1000 [mm] Diameter of sewage inlet:DN65 Diameter of overflow port:DN100 Diameter of flocculant inlet:DN20 Case vent flange:DN32 Hose:DN20 Tighten the hose clamp:20-32mm PUcorrugated pipe:ф140 quantity:1Set |

| Mixing device | Mixing spindle: material SUS304 Mixing blade: material SUS304 / specification:3mm quantity:1Set | |

| Liquid level switch | model | PS-3S Brand: OMRON |

| subject | Electrode: materialSUS316/ф6mm | |

| Mixer motor | power | 0.2[kw]×1 |

| Protection level | IP55 | |

| Insulation class | F | |

| quantity | 1Set | |

| brand | SEW | |

| Electric control cabinet | function | Frequency conversion control of dehydrator host and Realization of automatic and manual operation of dehydrator |

| material | Shell: carbon steel plastic spraying | |

| Electrical components | Components: air switch, relay and thermal relay are domestic first-line brands | |

| Supplementary note: the company reserves the right to make minor design changes in the above specifications | ||

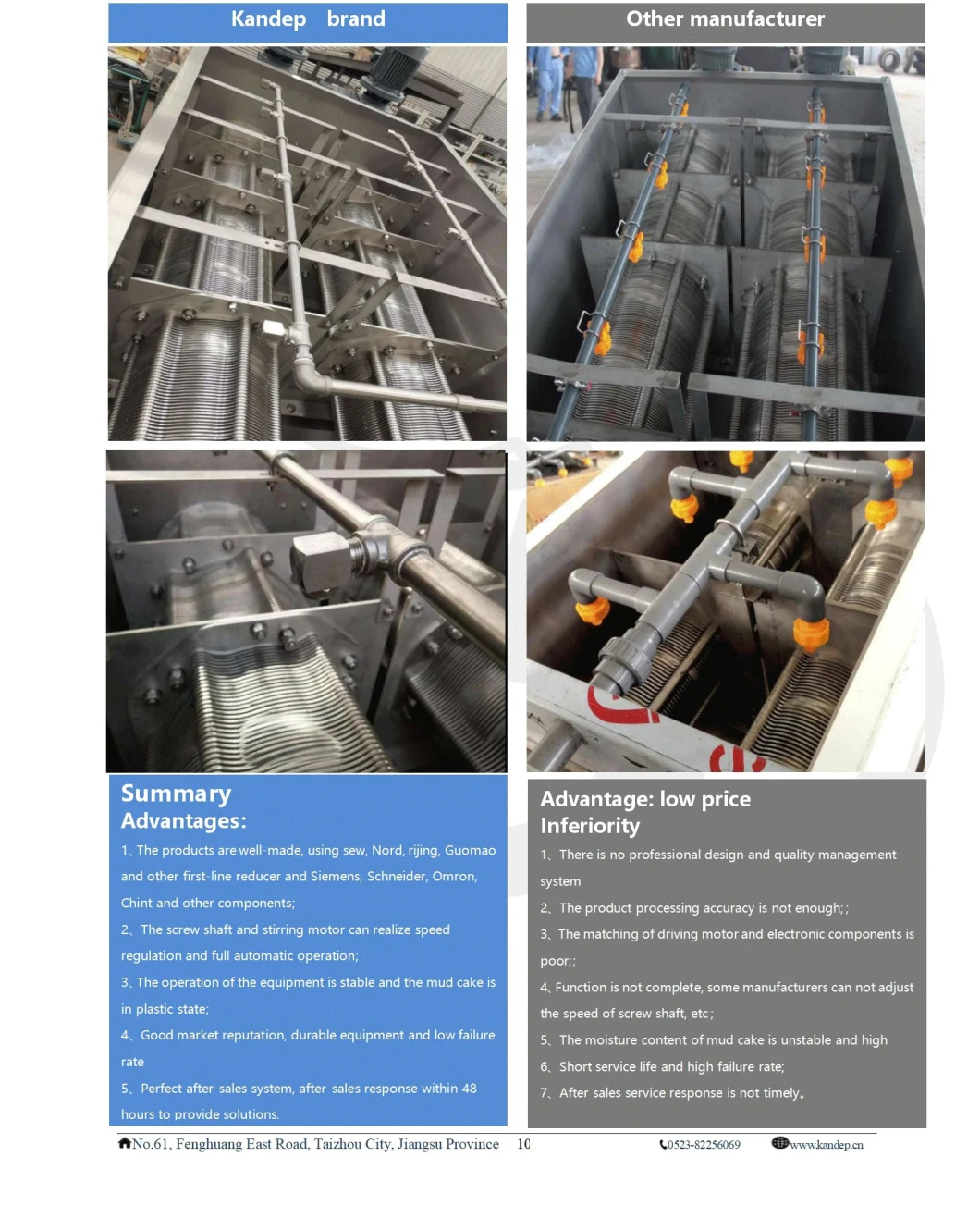

Summary

Advantages:

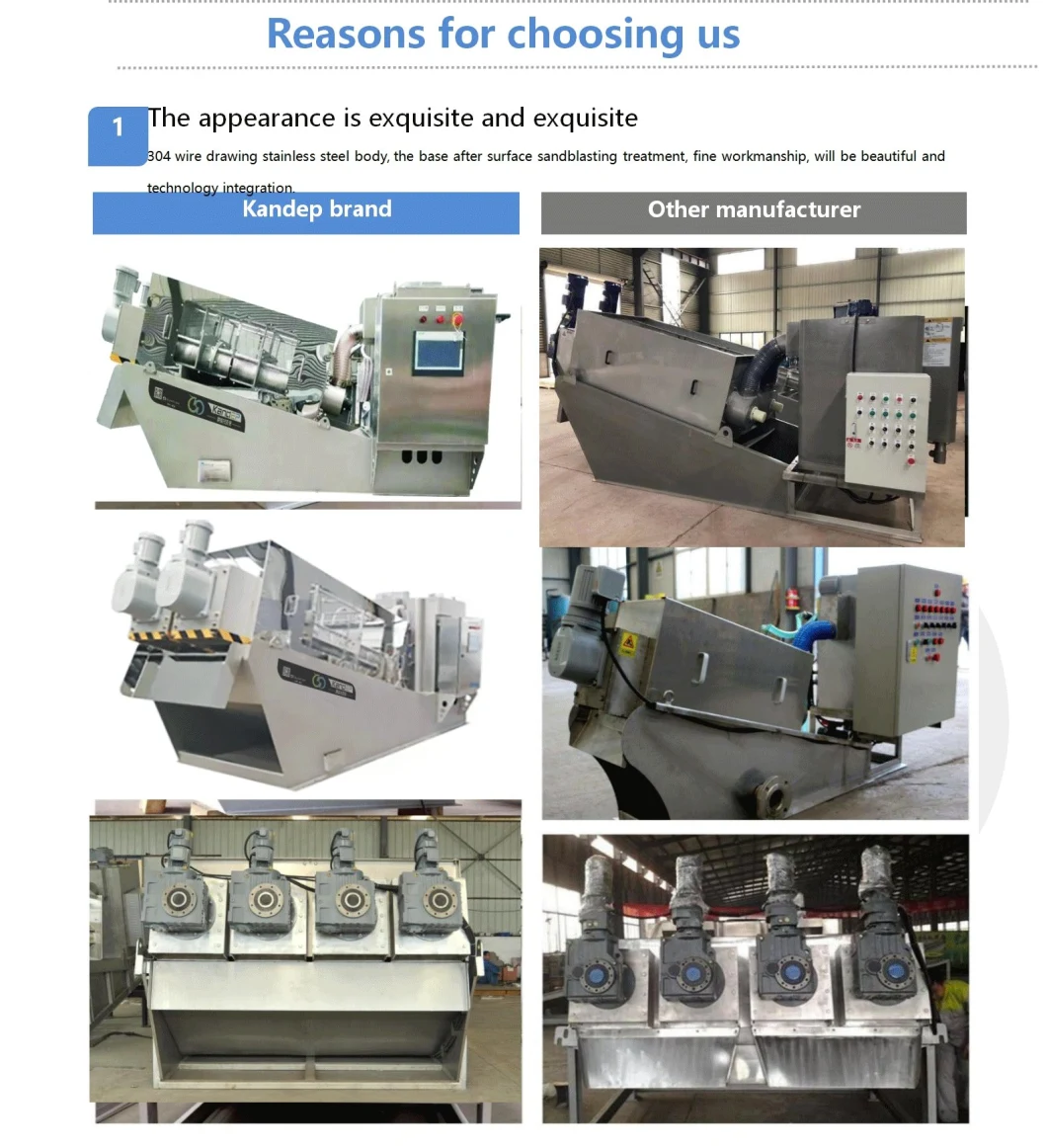

1,The products are well-made, using sew, Nord, rijing, Guomao and other first-line reducer and Siemens, Schneider, Omron, Chint and other components

2,The screw shaft and stirring motor can realize speed regulation and full automatic operation;

3,The operation of the equipment is stable and the mud cake is in plastic state;

4,Good market reputation, durable equipment and low failure rate

5,Perfect after-sales system, after-sales response within 48 hours to provide solutions.