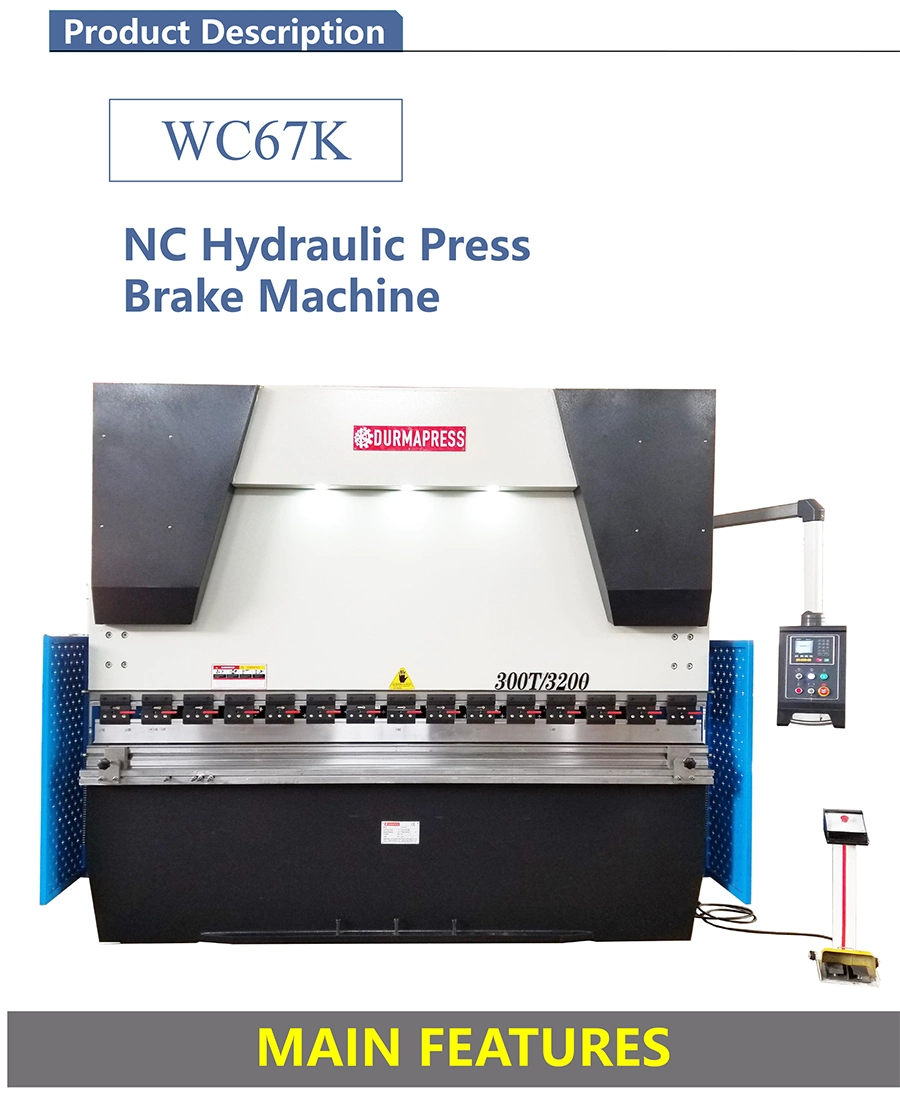

CNC Press Brake

The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicles and other industries.

Main Configuration

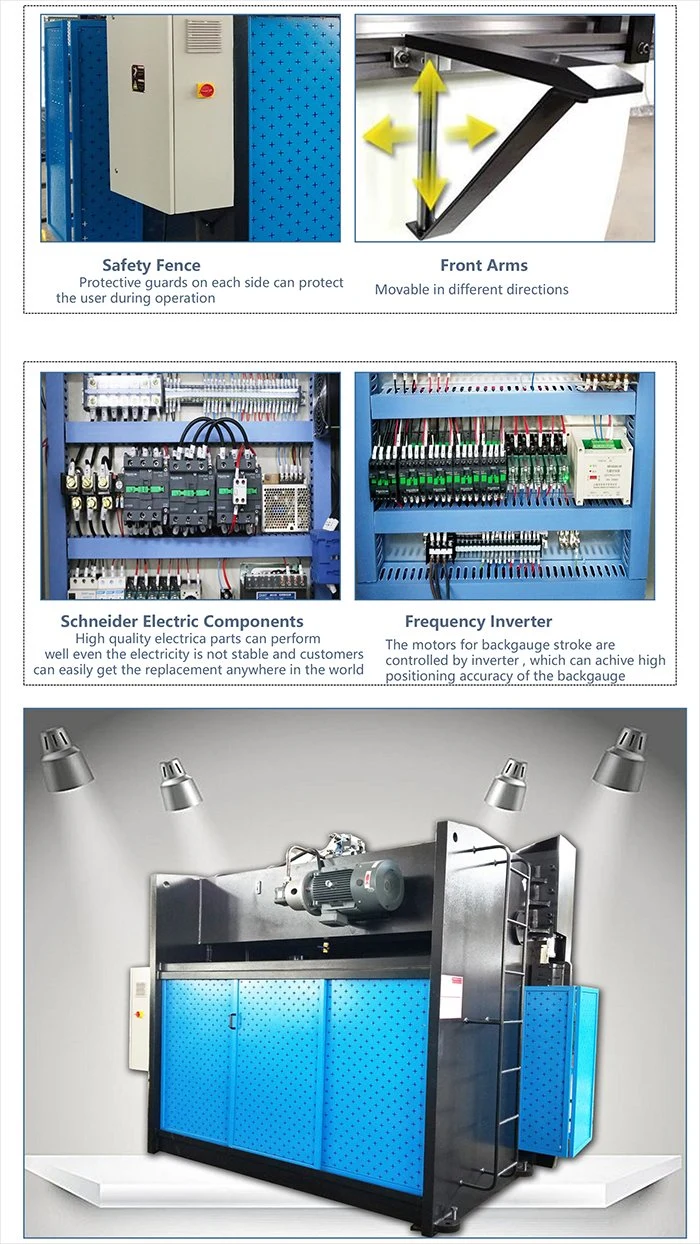

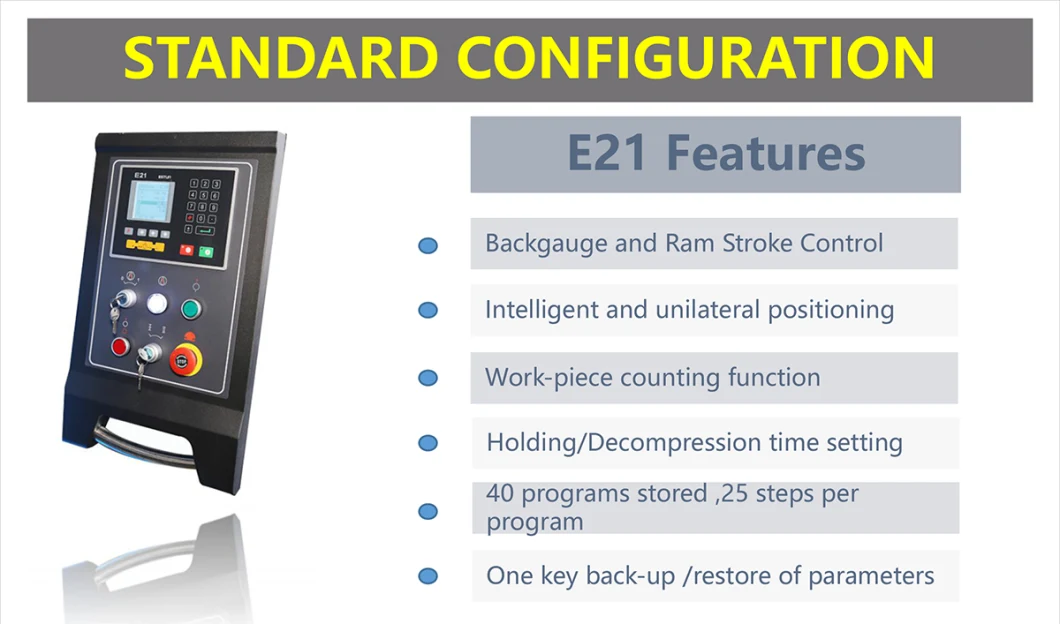

NC or CNC Controller

Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Automatic Mechanical compensation

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

Safety Equipment:

Safety Standards(2006/42/EC)

1.EN 12622:2009+a1:2003

2.EN ISO 12100:20110

3.EN 60204-1:2006+A1:2009

Main features

1. The whole machine is in sheet plate welded structure, which internal stress eliminated by vibration aging technology, high strength and good rigidity of machine.

2. Double hydraulic oil cylinder is applied for upper transmission, provided with mechanical limit stopper and synchronous torsion bar, stable and reliable operation, as well as high precision.

3. Electrical adjustment and manual fine-tuning adjustment mode are adopted for distance of rear stopper and stroke of gliding block, and fitted with digital display device, easy and quick in use.

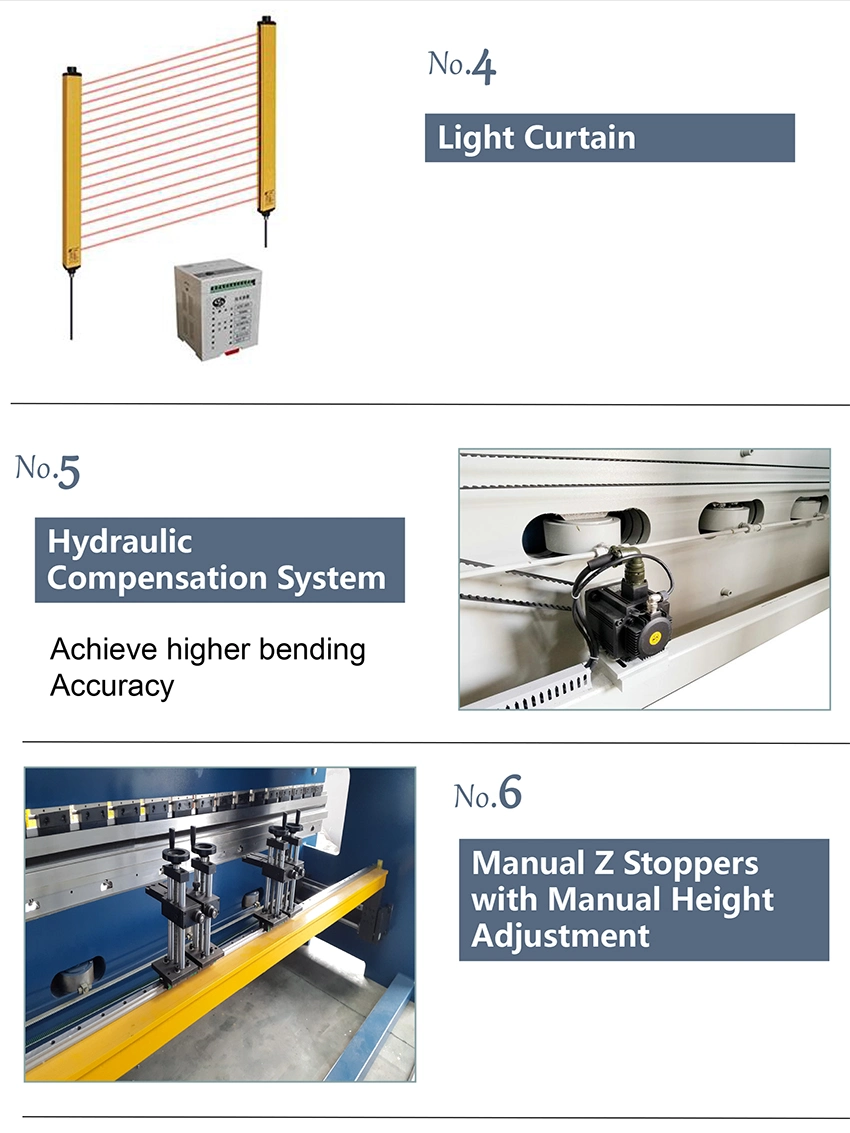

4. Upper clamp is fitted with compensation device.

5. Worktable mechanical compensation or hydraulic compensation device is optional.

Specification for WC67K 300T 3200

Our Services:

1.Installation Services

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and preoperation of machines. ( Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data.

1. For small and medium size machines ( machine height less than 2600mm ) we can use folklifter to load into container and unload the machine from the container. Container type we can choose 20GP , 40GP or 40HQ .

2. For big size machines (machine heigth more than 2600mm), because they are too high, can not use normal container to load. We can choose Open Top special container to load. Also We can use crane to hook into Open Top container and hook from the Open Top container .

FAQ :

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Main Configuration

NC or CNC Controller

Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Automatic Mechanical compensation

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

Safety Equipment:

Safety Standards(2006/42/EC)

1.EN 12622:2009+a1:2003

2.EN ISO 12100:20110

3.EN 60204-1:2006+A1:2009

Main features

1. The whole machine is in sheet plate welded structure, which internal stress eliminated by vibration aging technology, high strength and good rigidity of machine.

2. Double hydraulic oil cylinder is applied for upper transmission, provided with mechanical limit stopper and synchronous torsion bar, stable and reliable operation, as well as high precision.

3. Electrical adjustment and manual fine-tuning adjustment mode are adopted for distance of rear stopper and stroke of gliding block, and fitted with digital display device, easy and quick in use.

4. Upper clamp is fitted with compensation device.

5. Worktable mechanical compensation or hydraulic compensation device is optional.

Specification for WC67K 300T 3200

| Model | WC67K 300T 3200 |

| Normal Pressure | 3000KN |

| Worktable Length | 3200MM |

| Distance between holes | 2600MM |

| Depth of throat | 400MM |

| Ram travel | 250MM |

| Max opening height | 545MM |

| Main Power | 22KW |

Our Services:

1.Installation Services

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and preoperation of machines. ( Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data.

1. For small and medium size machines ( machine height less than 2600mm ) we can use folklifter to load into container and unload the machine from the container. Container type we can choose 20GP , 40GP or 40HQ .

2. For big size machines (machine heigth more than 2600mm), because they are too high, can not use normal container to load. We can choose Open Top special container to load. Also We can use crane to hook into Open Top container and hook from the Open Top container .

FAQ :

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant