Sludge Dewatering Micron Water Filtration PP PE Fabric Filter Press Cloth

Different materials of filter cloth used in different kinds of filter press .The material includes polyester, polyproplene, vinylon,chinlon, cotton cloth, twill mesh etc. which is used in sludge sewage treatment, coal and coal washing industry, tailings dry stacking treatment, red mud treatment and so on. Tell us your request and we will choose the most suitable cloth for you!

Filter cloth producing process:

Automatic loom for producing cloth: imported materials and machine from German

Feeding pulp efficiency: decrease by 5% after 10days, and decrease by 10% after 60 days.

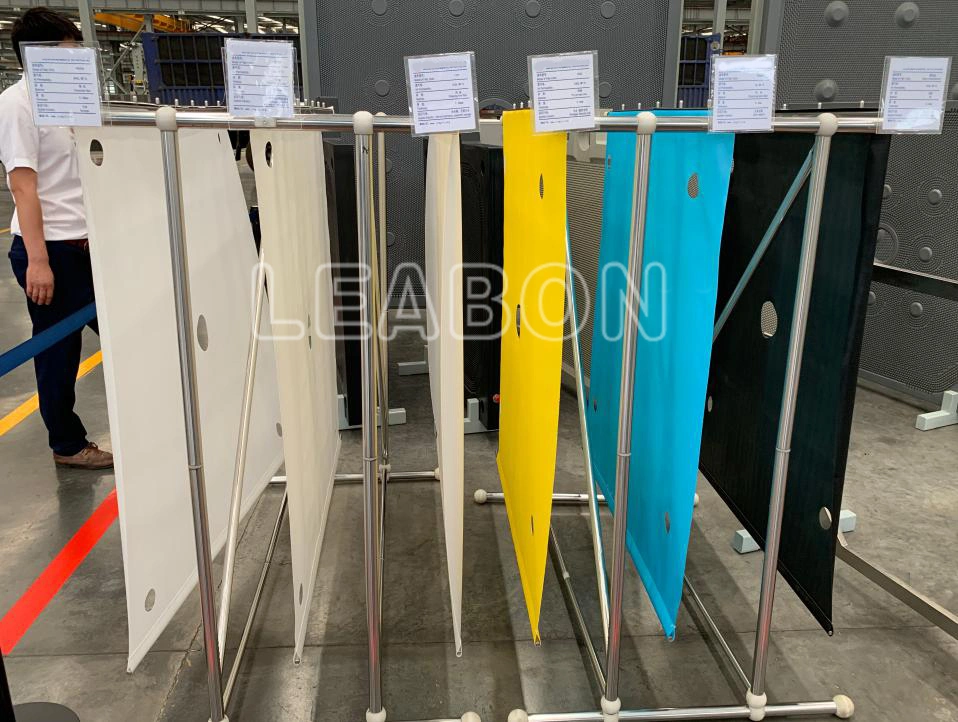

Different types filter cloth:

In order to achieve better filtering requirements, we introduced a complete set of German filter cloth production line and technology. By

virtue of 30 years of filtering experience, the heavy German rapier looms weave the thinnest silk threads into filter cloth of high density

and different hole patterns by using 0.3-3.5 tons beating-up force after each weft across warp.Under same area the filtration holes of filter

cloth are 20%-50% more than other filter cloth, which improve the filtration speed greatly. The filter cloth was woven under constant

temperature and humidity, which eliminate the fabric burrs caused by static electricity. What's the most important is that monofilament

filter cloth can make the filter cakes fall off automatically, which has conquered the unsolved problem ever since.

FAQ:

1. How to buy your interested products?

You can provide us the water sources, water quality, flow rate and ground area, material requirements about your project (More details, please contact us).

2. How to pay?

L/C or T/T are acceptable.Usually, 50% payment in advance, 50% payment before delivery.

3. What is the delivery time?

It depends on order quantities. Generally speaking, the delivery time will be within 2months.

4. How to pack the products?

We use standard export package.If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

5. How to install after the equipment arriving destination?

We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

6. How long is the validity?

The validity is 12 months after installation.

Our service:

(1)Pre-sales service

a. Sales team will suggest suitable project.We can design and manufacture products as per your special requirements.

b. Technical team analyse and design for you.

(2)After-sales service

a. Assist you build up factory .

b. Install and maintain machines.

c. Training your workers to achieve skillful operation.

d. Offer technical support through telephone or online videos at any time.

Contacts: