1.Strengthen polypropylene filter plates and flame are made through mold pressing with the features of high strength,light weight,strong corrosion resistant,non-poisonous and no smell.

2.Adopt hydraulic pressing with the maximum pressure pressure of 25Mpa and automatic pressure maintaining by using electrical connecting pressure gauge.

3.Simple in operation,convenient in maintenance and safe in operation with multiple

safety device.

Introduction of Sealed Filter Press

1.The slurry materials are sent to filter chamber by the pressure of feeding pump. Then filtrating media(filter cloth) separates solid and liquid in slurry material. When solid in slurry becomes cake shape, air is sent to diaphragm to fully squeeze the solid to reduce moisture content. If users have high requirements about filtration of sticky material and moisture content ratio, this machine has its own special characteristics to meet the needs.

2.It is available in manual, semi-automatic, and fully automatic units incorporating PLC control and automatic cake slagging system. You can easy to use our machine.

Advantage

1. Easy to replace filtering cloth.

2. Increased product throughput

3. Reduction of the residual moisture of the filter cake

4. Shorter filtration, wash and cake cycles

5. Optimized cake structure and make the final cake drier

6. Automatic drawing plate, easy to discharge.

7.The highest filtering pressure can be 2Mpa.

Some Models of Recessed Closed Filter Plate

1.It is a new type of filter plate,which is made of high-strength polypropylene and molded by one time.

2.Afer the filter plate is compressed,it is in the sealed state among the chambers,avoiding the liquid leakage and volatile of odor in the process of filtering and discharging .

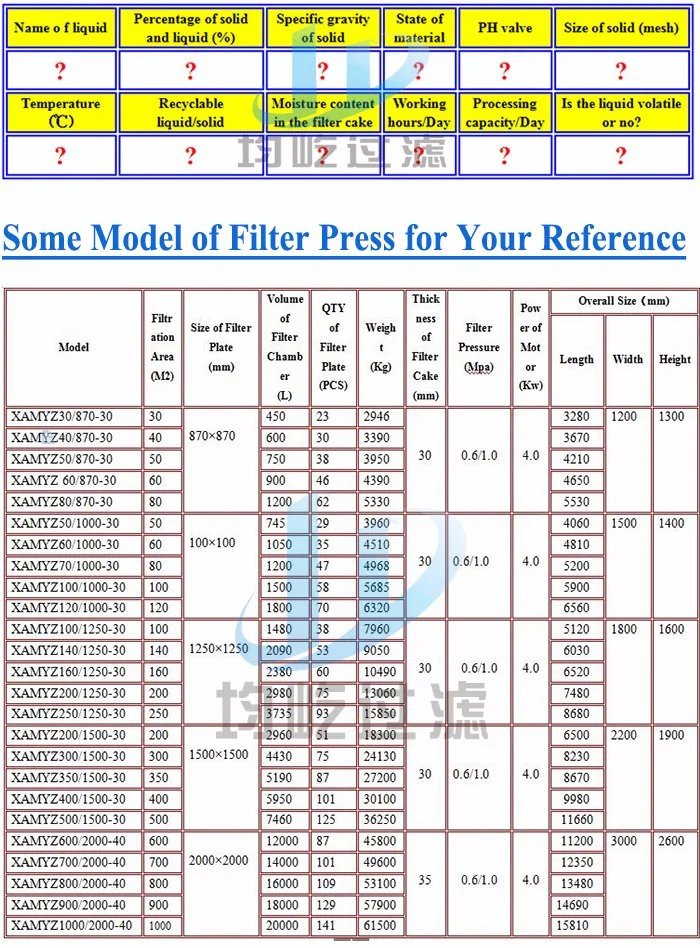

Before we made the exact quotation,please tell us the following parameters:

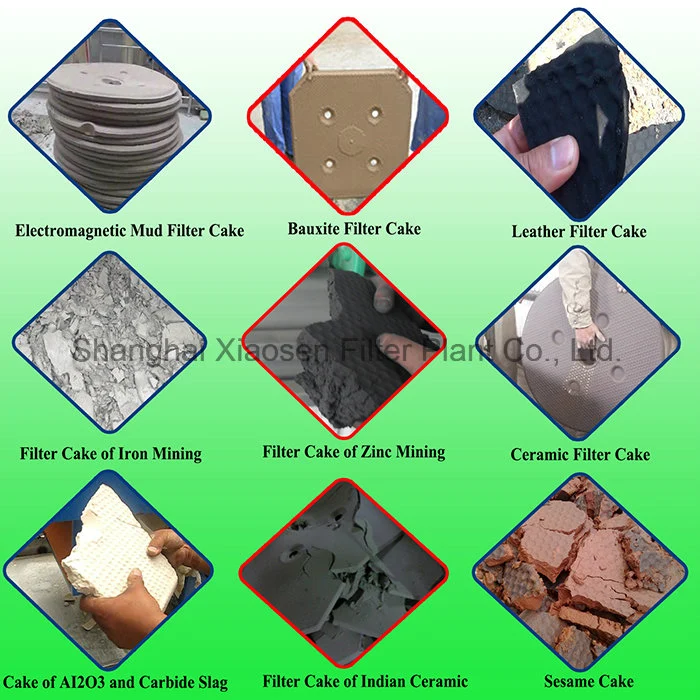

Different kinds of the cake after it is processed by the filter press

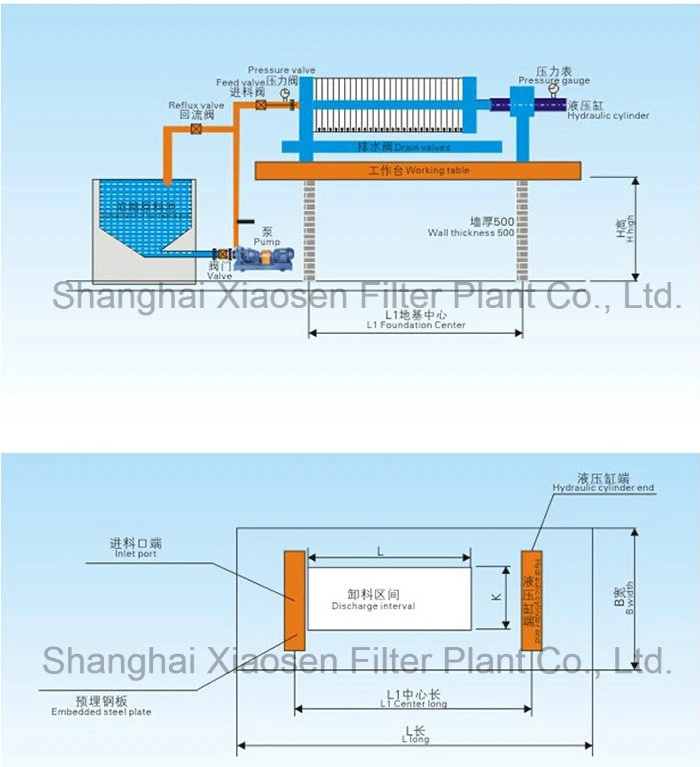

Schemetic Diagram of Fitler Press

Pre-sale and after-sale service

Pre-sale service:

1.Your inquiry will be replied within 6 hours.

2.Help you to select suitable model

3.Design totally according to your requirements

After-sale service:

1.Provide 12 months warranty period and you will have our technology support forever

2.Engineering available to offer the service to your machinery overseas

Frequently asked questions

1.Q: Can you provide us the detailed drawing?

Yes, we can provide you the drawing after have made the prepayment.

2.Q: Are you a manufacturer or a trader?

We're a professional and experienced manufacturer located in Shanghai.

3.Q: Can you accept OEM?

Yes, we can produce the machinery totally according to your design standard.

4Q: How about the delivery time?

Normally 10-20 working days after prepayment, and we promise we will make the delivery as soon as we can.

Customer Visiting on Peru Expo Mina Fair

Contact us