What is the Electric Motor Drive Mechanical Filter Press

Motor Drive Mechanical Filter Press is driven by the motor to push the compression plate by the

transmission parts to press the filter plate.The compressing screw and the retaining

nut are designed to have a reliable self-locking angle to assure the reliability and

stability when it is pressed.It is controlled automatically by the motor comprehensive

protector and protect the motor overheating and overload.

Application

It is widely used for small treatment factory in the following industry:

Effluent treatment plants: Textile, Paper, Leather, Jute, Sewages, Industrial and municipal waste water

Ceramics: Clay, Porcelain, Fine earth, Marble and Granite

Metallurgy: Electroplating and Electro Polishing, Steel Mill Waste, Nickel, Copper, Zinc Lead, Silver

Pharma Industries: Antibiotic, Syrup, Intermediates and Bulk Drugs

Chemical Industries: Basic Chemicals, Organic and Inorganic, Resins, Starch, Enzymes, Pesticides, ActivatedClay, Phosphoric compounds, Marine Chemicals

Dye Stuffs: Pigments, Dyes, Intermediates

Food Industries, Vegetable Oils, Cane Juice, Food Colors Soups, Distilleries, Dairies and Hotels

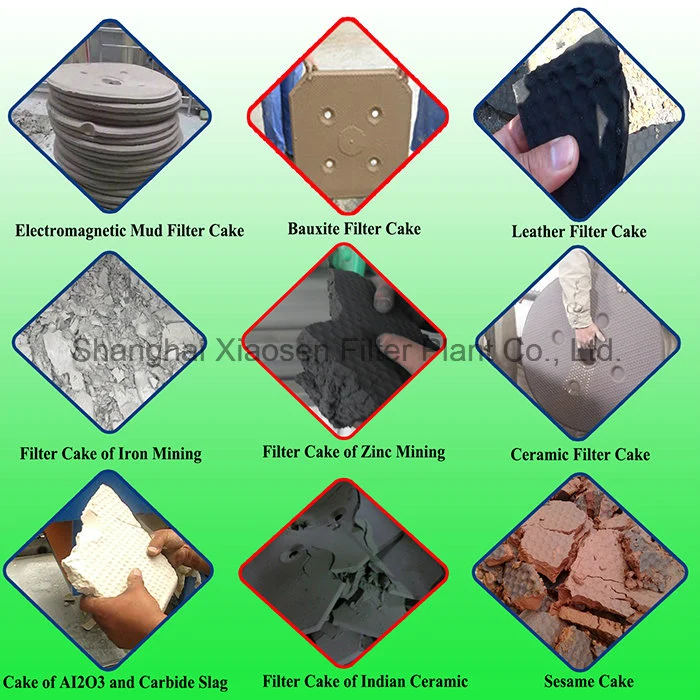

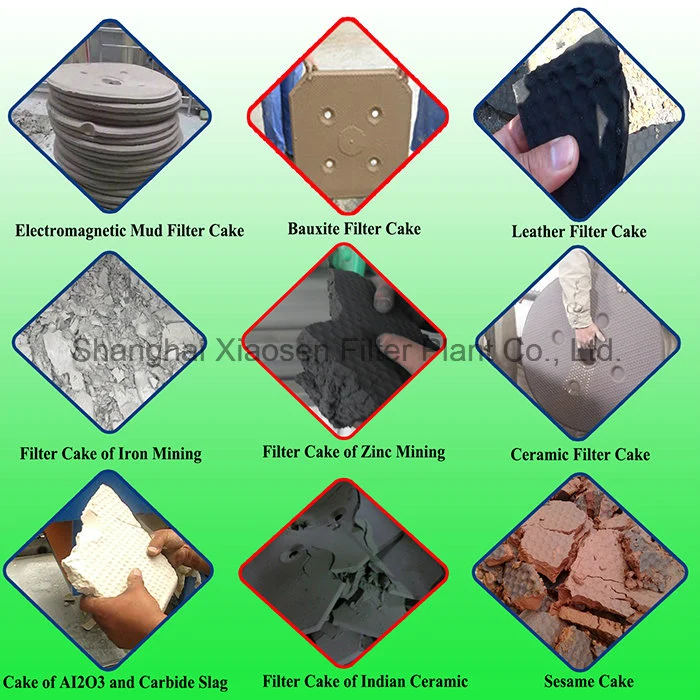

Different kinds of the cake after it is processed by the filter press

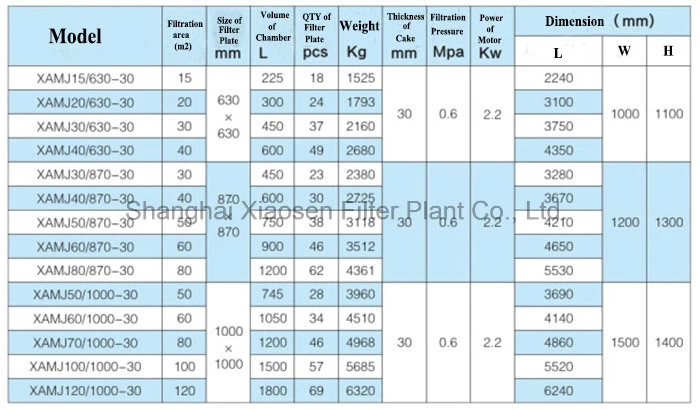

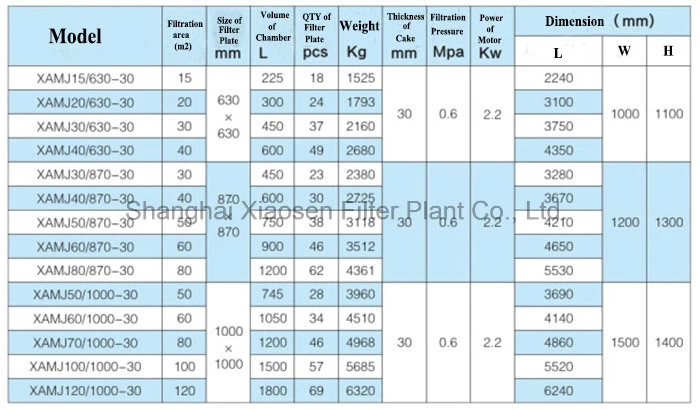

Parameter of Electric Motor Drive Mechanical Filter Press

Parts with fine processing decides the quality of filter press

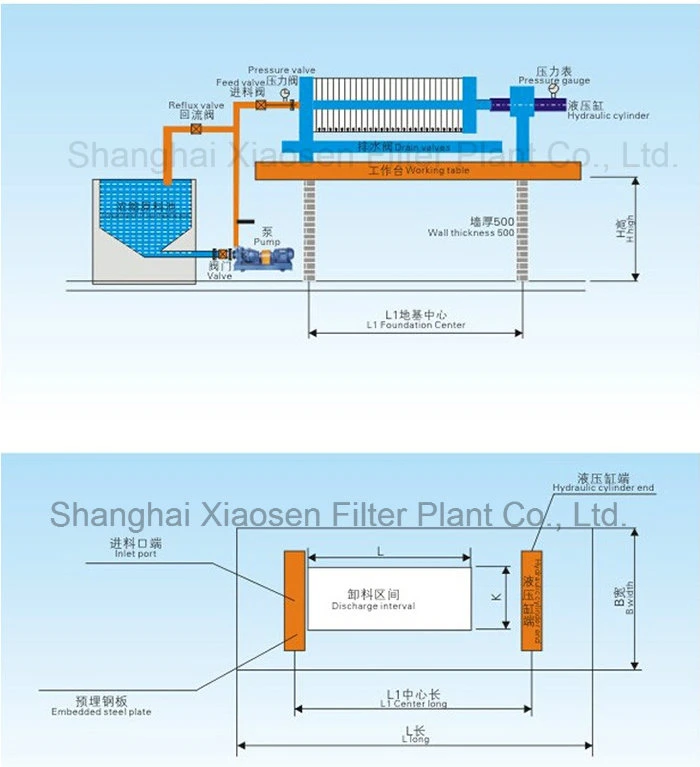

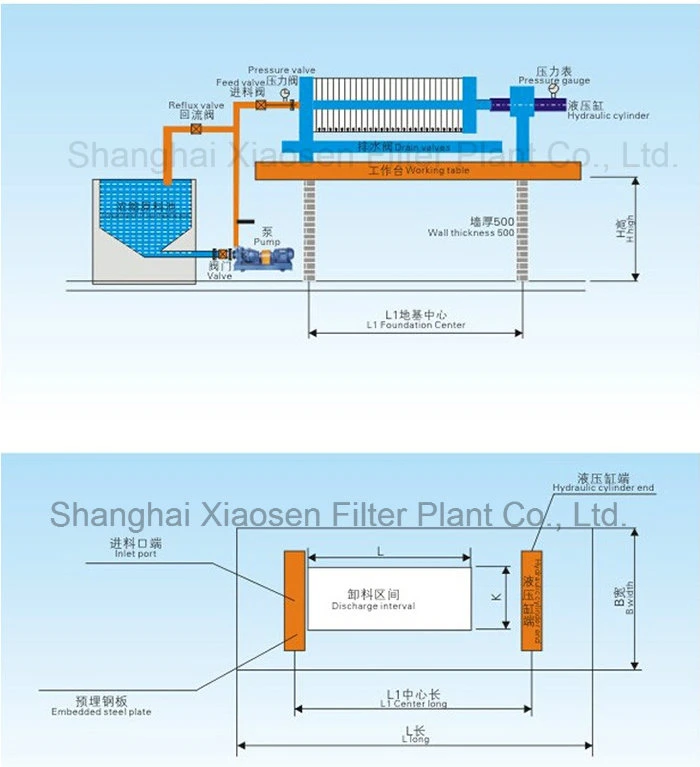

Schematic Diagram of Filter Press

If you need or want to know more details about any kinds of the filter press,please be free to contact us.

Motor Drive Mechanical Filter Press is driven by the motor to push the compression plate by the

transmission parts to press the filter plate.The compressing screw and the retaining

nut are designed to have a reliable self-locking angle to assure the reliability and

stability when it is pressed.It is controlled automatically by the motor comprehensive

protector and protect the motor overheating and overload.

Application

It is widely used for small treatment factory in the following industry:

Effluent treatment plants: Textile, Paper, Leather, Jute, Sewages, Industrial and municipal waste water

Ceramics: Clay, Porcelain, Fine earth, Marble and Granite

Metallurgy: Electroplating and Electro Polishing, Steel Mill Waste, Nickel, Copper, Zinc Lead, Silver

Pharma Industries: Antibiotic, Syrup, Intermediates and Bulk Drugs

Chemical Industries: Basic Chemicals, Organic and Inorganic, Resins, Starch, Enzymes, Pesticides, ActivatedClay, Phosphoric compounds, Marine Chemicals

Dye Stuffs: Pigments, Dyes, Intermediates

Food Industries, Vegetable Oils, Cane Juice, Food Colors Soups, Distilleries, Dairies and Hotels

Different kinds of the cake after it is processed by the filter press

Parameter of Electric Motor Drive Mechanical Filter Press

Parts with fine processing decides the quality of filter press

Schematic Diagram of Filter Press

If you need or want to know more details about any kinds of the filter press,please be free to contact us.