50tph River Sand Dewatering Spiral Washing Machine For Sale

Sand Dewatering Machine is widely used to combine with the ball grinder in a closed circulation for ore sand separation in the ore separation plant., classify ore sand and fine silt in the gravity separation plant, classify the granularity from the pulp in the metal ore beneficiation flow and remove the slime and water in the ore washing process.

Introduction of Sand Dewatering Machine

The Sand Dewatering Machine can class the finely milled materials by particle size, fine particles suspended in the water become into the overflow outflow, coarse particles sink to bottom, by the screw pushing into the upper and return to grinding machine, the machine is also used to separate fine clay in the minerals and used for ores dehydration.

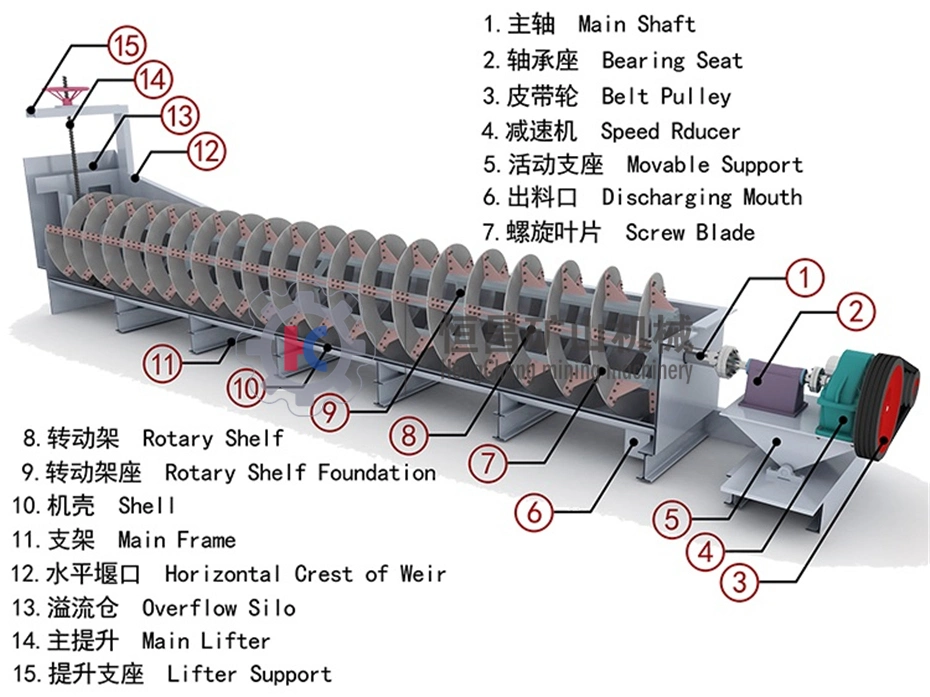

Spiral: It is the main components of this machine, it formed by the main shaft, frame, spiral blades, lining iron frame. The frame, spiral blades, linked iron are formed to connected spiral surface, because the shaft is constantly rotating, so the role of helical face is mixing the slurry , make fine particles flow from the overflow weir, coarse mineral particles conveyor from the screw first to discharge port.

Cell: Welded by steel plate and shaped steel, it is the body of screw classier.Lifting mechanism: The movement of machine screw parts is achieved through the cycloid reducer, gear, screw. When classifier stop working, the materials in the water chute will precipitated, in order to avoid damage by precipitation and the transmission will occurs over load when it move again, so must lift the screw spindle from water chute and make it leave the precipitation level, for this design lifting mechanism.

Technical Parameter of Sand Dewatering Machine

| Model | Spiral diameter (mm) | Trough length(mm) | Spiral rotate speed (mm) | Processing capacity (t/d) | Motor power (kw) | Dimensions (mm) | Total weight(t) | ||||

| Sand return | Overflow | For driving | For lifting | Length | Width | Height | |||||

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | ---- | 5430 | 680 | 1480 | 1.9 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | ---- | 6720 | 980 | 1820 | 3.1 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | ---- | 7590 | 1240 | 2380 | 4.9 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | ---- | 9600 | 1240 | 2680 | 6.2 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 43054 | 3 | 10790 | 2530 | 4490 | 20.5 |

| FC-20 | 12900 | 3210-5940 | 320 | 43054 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 | 26.8 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | 41 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 | 73 |

| 2FC-30 | 14300 | 23300 | 1410 | 40 | 8 | 17091 | 6640 | 8680 | 84.8 | ||